The First Dutch Bone-China Pipe

Author:

Don Duco

Original Title:

De eerste Nederlandse Bone-China pijp

Publication Year:

1987

Publisher:

Pijpenkabinet

Description:

Discussion of a tobacco pipe in Bone-China porcelain designed by Royal Goedewaagen in Gouda, the Netherlands.

The traditional clay tobacco pipe, produced under pressure in a metal mould, is generally regarded as having a definite, unchanging and fairly inflexible bowl style. When rather expensive iron or brass moulds were made, these stayed in use for a long period and as a result the development in the shape of the clay tobacco pipe was rather slow.

At the beginning of the twentieth century a change took place when a new method of pipe producing was developed among the Gouda pipe makers in Holland. Some of the larger firms went over from moulding stiff clay in metal moulds to using liquid clay in plaster moulds. With this new process a more rapid development in the shape of pipes began as, for a well-shaped product, a plaster mould could only be used 20 to 30 times, due to the plaster quickly becoming worn. Renewing the styles of pipes was a constant necessity for the pipe maker, both to stay competitive and also to have the most modern pipe available for the ever critical smoker who, by this time, had a wide range of relatively cheap briar pipes to choose from. The new pipe styles were adapted from original clay pipe forms and also from meerschaums, briars and other pipes.

Developing a new style meant designing a new pipe which was normally done in plaster. The plaster pipe, usually a massive bowl (Fig. 1), was waxed or soaped and then the first mould was made. After refining the style of the pipe in the first mould, the so-called ‘sleutels’, (literally keys) are added, for closing both halves of the mould. From this the production mould is made, which shows the pipe in positive, and this is then used to make the finished moulds for the pipe production. Although the working methods of the negative and positive mould looks quite complicated, the pipe manufacturers soon became familiar with using plaster, a material which was cheap in price and easy to work.

The design of the pipe, plus the first mould, are carefully kept for eventual new productions at a later date. From the production mould the moulds for normal use are made, until this also gets worn and a new production mould has to be made from the first mould.

Making pipes in plaster moulds is quite simple. Pipe clay is made into a liquid and poured into the plaster moulds. The water is sucked onto the porous plaster and a clay-wall is made in the mould. When this is of the desired thickness, the surplus clay is poured out. The mould and pipe are sent for stoving and when the pipe becomes a little stiff and shrinks, it loosens itself from the mould and can then be removed. When almost dry (leather dry) the taps of the mould are removed with a knife, the seams are flattened with a sponge and the pipe is ready for the first firing. After this the glaze, which makes the pipe strong and shiny, is applied and it is fired for a second time. Usually only bowls were made which were then mounted on rubber or vulcanite stems by means of a metal ferrule.

Knowing the manufacturing method, and considering the various styles which were produced since the introduction of this method in about 1900, one sees a wide range of interesting shapes and designs in all these types of pipe.

The pipe illustrated (Fig. 2) is remarkable in the endless lines of new designs, not so much because of its style but because of the material of which it was made. The pipe is called bonair and was made by Royal Goedewaagen in Gouda, Holland.

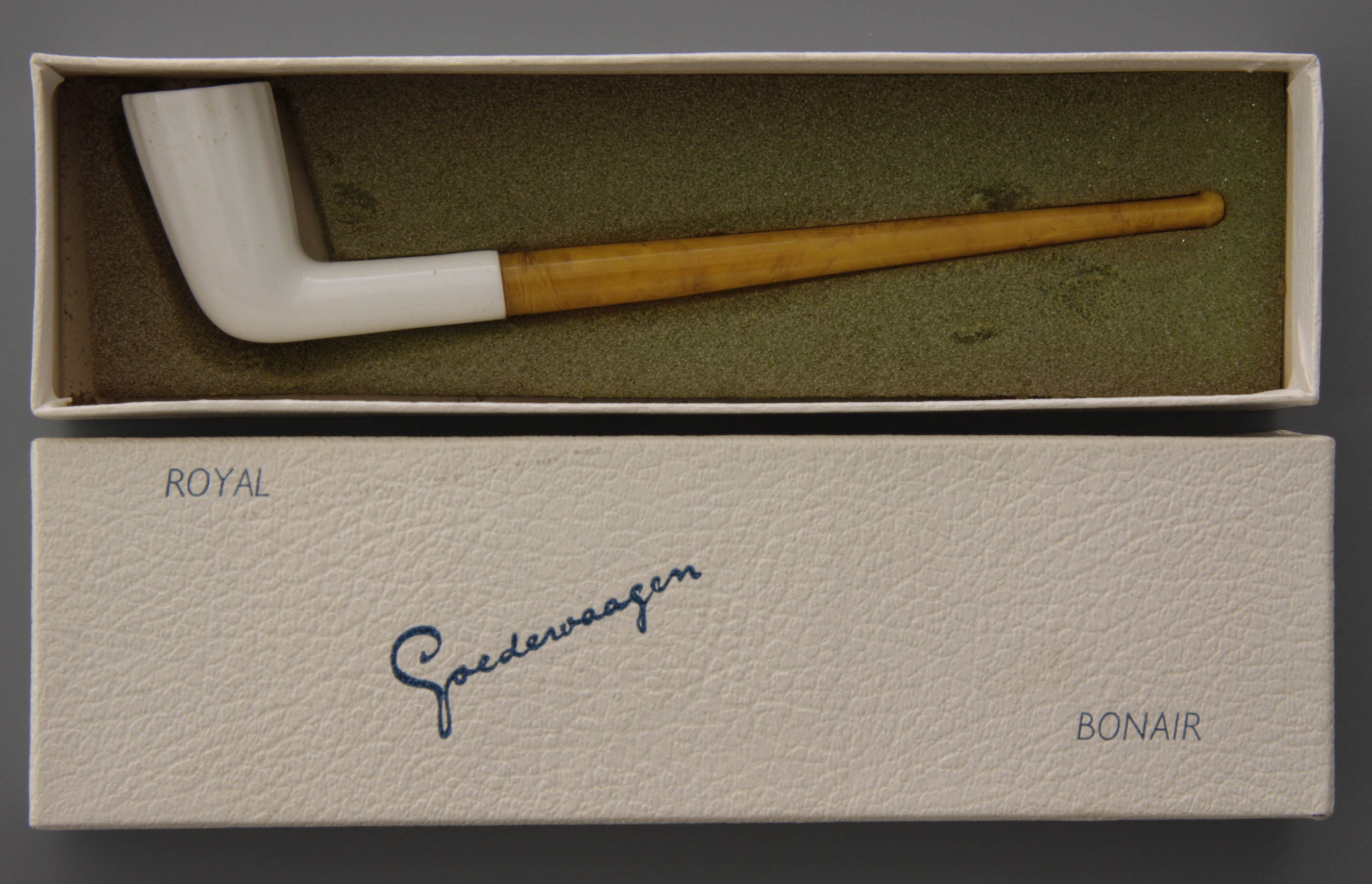

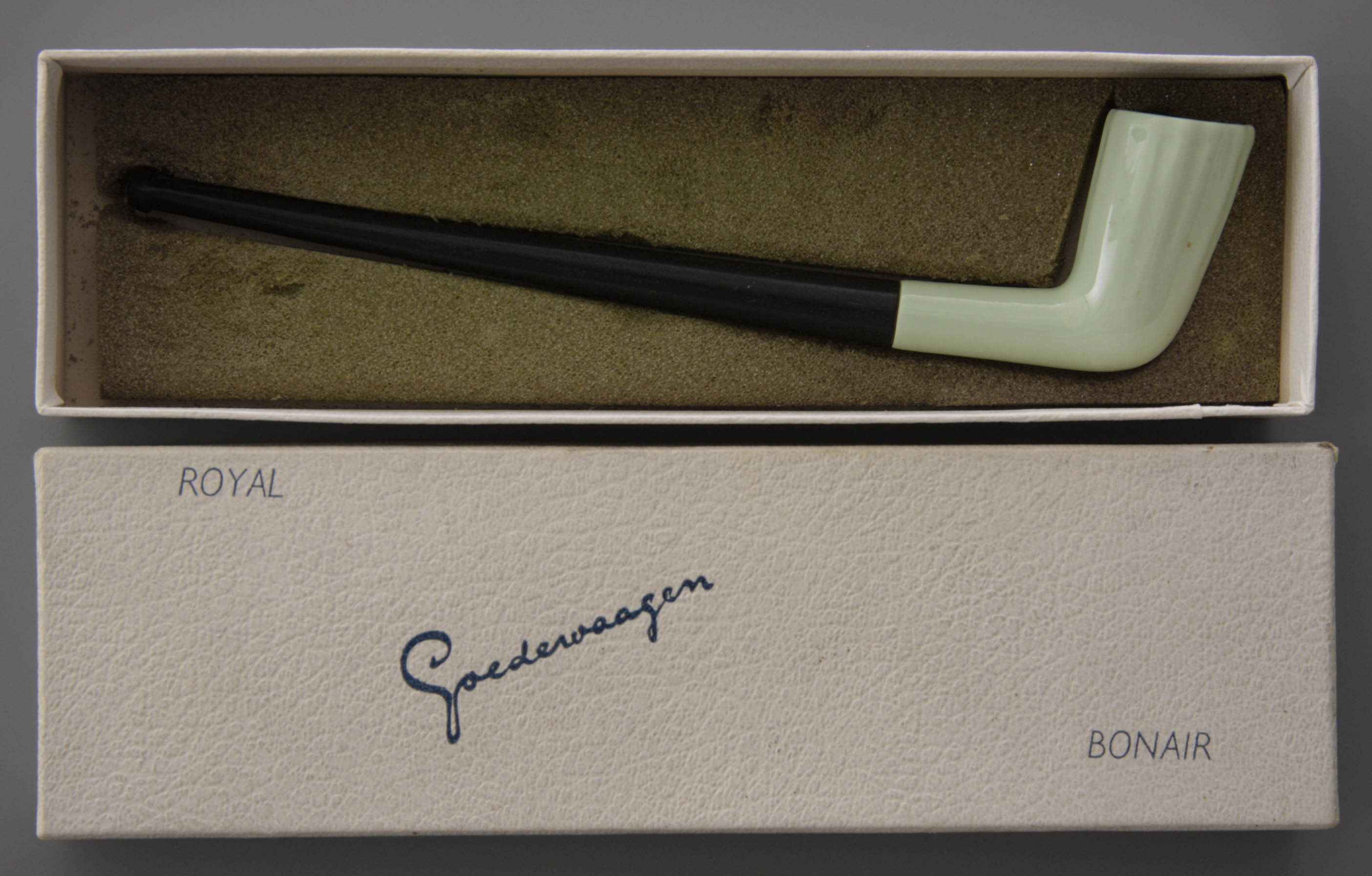

A close study of the material shows that the pipe is not made of the normal and traditional pipeclay, but of bone-china. The clay mixture is finer and harder than pipe clay, it is slightly transparent but not porous. The ingredients of the clay are porcelain clay mixed with Cornish stone and bone ashes. This type of material was developed at the Goedewaagen factory during the years 1958 to 1960, following the method already in use at the factories near Stoke-on-Trent, England. The bone china was mainly meant for the production of cups and saucers, which were one of the main products of the Goedewaagen firm at that time, since they had turned over to ceramics when the pipe industry collapsed. However, in honour of their history as a pipe factory, pipes were also made of this clay. The bonair was made in three colours – white, light yellow and very light green (Fig. 3). The pipe was sold in boxes of three bowls and one stem in luxury paper (Fig. 4). The gift box measures 7,5 x 6 inches (19 x 15 cms). There was also another box containing just one pipe (Fig. 5).

The pipe was generally praised because the porcelain stayed perfectly white and became extraordinarily hot, so the tobacco brunt better and could be smoked to the final pinch, making it economical to smoke. For smokers this is astonishing as this short stemmed pipe with its hot bowl gives a tasteless hot smoke.

Bonair was never very successful. Complaints were soon made about the bursting of bowls, which was a greater risk to those who smoked the pipe rather heavily.

Production of this novelty lasted less than one year. As far as we are aware it was never advertised and now, nearly thirty years later, examples are rarely found. A typical example of fast development in these types of pipes!

© Don Duco, Pijpenkabinet Foundation, Leiden – the Netherlands, 1987.

Illustrations

- The massive plaster design for the bonair. Gouda, Koninklijke Goedewaagen, shape 945, 1958-1960.

Leiden, Pijpenkabinet collections Pk 6.236

- The bonair by Goedewaagen with a white bone China bowl. Gouda, Koninklijke Goedewaagen, 1958-1960.

Leiden, Pijpenkabinet collections Pk 10.074a

- The bonair by Goedewaagen with a green and a yellow bone China bowl. Gouda, Koninklijke Goedewaagen, 1958-1960.

Leiden, Pijpenkabinet collections Pk 10.074b, Pk 10.075

- The bonair gift box containing three bowls in different colours and one pipe stem. Gouda, Koninklijke Goedewaagen, 1958-1960.

Leiden, Pijpenkabinet collections Pk 4.256abcd

- The bonair single in a box. Gouda, Koninklijke Goedewaagen, 1958-1960.

Leiden, Pijpenkabinet collections Pk 10.074

Postscript

In his publication "Koninklijke Goedewaagen, een veelzijdig ceramisch bedrijf (a versatile ceramic company)" (Leiden, 1999) Don Duco discusses the production of Bone China with other designs such as table ware (p.154-156).